A Safer Prop That's Sea Life Friendly

Turning Point Propellers, Inc. has partnered with the Inventor of the ESP™ Safer Prop, Colin

Chamberlain, and secured Worldwide Marketing and Production rights for an exciting new propeller.

With worldwide patents either granted or in process, the technology is now being introduced to the

marine market.

The NEW Aegis Propeller System uses unique geometry to produce a propeller that will minimize the

potential damage from a prop strike to marine mammals, turtles, and other sea life at low boat speeds.

It will also reduce the occurrences of incidental contact injury by bathers and boaters when the boat is

at idle or stopped.

Aegis is the result of a decade of intensive study of hydrodynamics, propeller geometry and fluid

flow. Extensive testing of over 100 prototypes in Australia and the United States allowed for fine tuning

the final product to produce slow speed impact mitigation while still delivering excellent top end speed,

cornering ability, and overall performance. A Safer Prop that Performs!

Click here for more information and the Aegis application chart(pdf).

US and Global Patents Granted or Pending

Damage Indicator

The Aegis Propeller features a unique green multi-coat finish, making the prop immediately recognizable on the boat and in the water. A red Safety Coat shows through the green top coat in the event of edge damage. This will alert the boater of the need for service by a Turning Point approved propeller repair facility to maintain the Safer Edge Technology in like-new condition.

Proprietary Stainless Steel, TP17™

Formulated to meet the exacting requirements of the new Aegis design. 20% higher chromium content than the competition - more shine, better corrosion resistance. Almost 250% Stronger and 5X more durable than run-of-the-mill stainless steel. This new material allows Turning Point's Engineers and Designers the freedom to produce radical new designs that will help you wring the most performance out of your boat.

MaxSpeed™ Dyno Balance Processes

Aegis Propellers will be produced utilizing state-of-the-art stainless steel casting technologies. Gives your boat a smoother running ride, higher top end speed, and increases fuel economy. This process is standard on every prop and is only offered as a costly option from other manufacturers. (Exclusive on all Aegis, Express Mach3, Express Mach3 OS, and Express Mach4 Propellers)

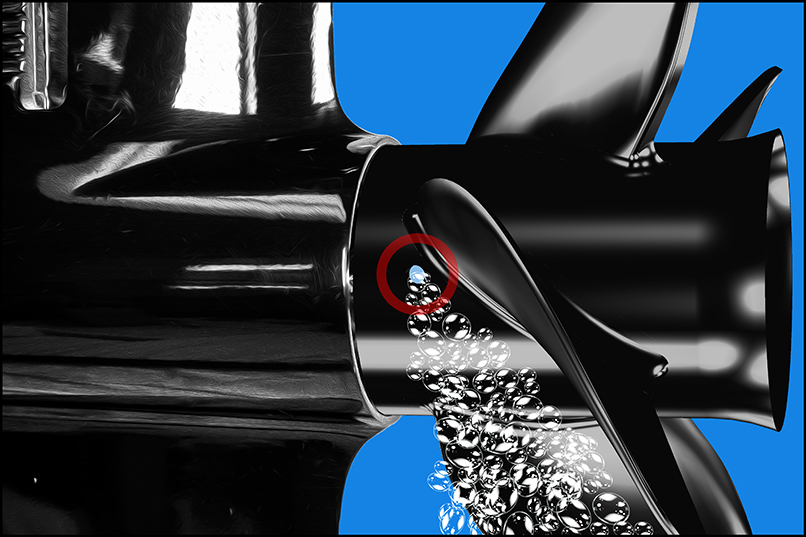

Large Free Flowing Exhaust Ports

Turning Point's Propeller Housings have massive Exhaust flow pathways. Their Propellers have 40% more exhaust flow Area versus competive product. More exhaust flow and less backpressure can generate more horsepower. Like headers for your boat.

| Turning Point's Exhaust Ports 40% Larger | Competitor's Exhaust Ports (Restrictive) |

Tuned Vents for Fast Acceleration

Aegis Stainless Steel Propellers have vented

barrels for hole shot/low end acceleration.

Turning Point is still the only manufacture

to offer this race proven technique in their aluminum line of propellers. Wake-Boarders and water skiers get out of water faster.

(select models only 13" and 14" diameter 15+ Pitch).

Turning Point Aegis® stainless steel boat propellers are designed for 25(Bigfoot)-300+hp Evinrude®, Force®, Honda®, Johnson®, Mariner®, Mercruiser®, Mercury®, Nissan®, OMC®, Parsun®, Suzuki®, Tohatsu®, Volvo® Penta®, and Yamaha® Outboards and Sterndrives. They are available in 3 blade right rotation models with a variety of diameter and pitch options to run on most common boat types.

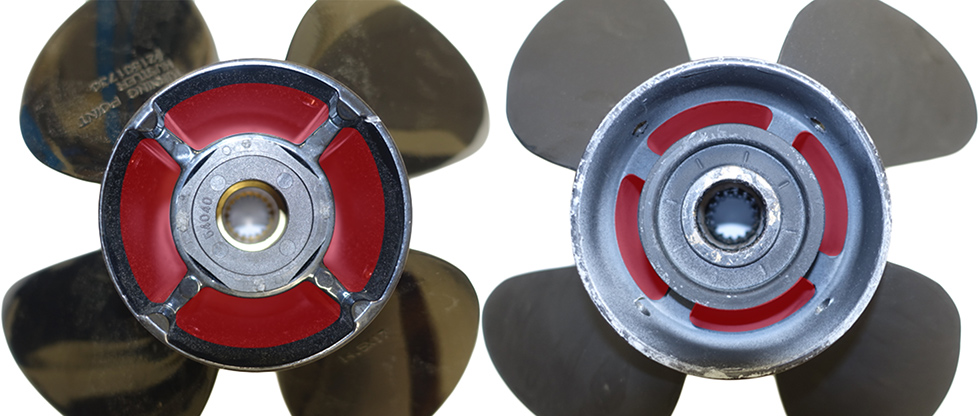

Exclusive Lifetime Warranty Hubs

Turning Point is the only company to offer MasterGuard®

Installation kits and prop housings for 6-300+hp engines with a Lifetime Warranty

Hub. Boaters save up to 38% when buying a replacement propeller housing.

MasterGuard hubs are Re-useable most of the time after a prop strike, and if

not, they are Warrantied even if the prop is Destroyed. These hubs offer

enhanced lower unit protection.

Turning Point's MasterGuard Hubs are engineered to withstand typical wear and tear

over time without risk of spinning or failure under normal operational use. Turning

Point's unique patented one piece hub with glass filled nylon over durable marine bronze splines

eliminates failures commonly seen in multi-part "sleeve and spline" designs, and

pressed-in rubber hub systems.

Covered by US Patent #6,471,481, #6,685,432, #7,717,678 and

worldwide patents with additional patents pending.

Eliminate Hub System Vibration and Chatter

Innovative one piece design reduces the number of parts and eliminates failures commonly seen in multi-part hub systems.

Eliminate Hub Cracking and Failure

The glass reinforced high-tech polymer construction increases flexibility, eliminating potential material stress fractures.

Corrosion Resistant Materials

Premium corrosion resistant durable marine bronze splines.

Reduce Gear Shock and Engine/Drive Damage

MasterGuard hubs offer Shock absorbing high-tech polymer cushion with lower unit protection with 1000ft/# break point.

Easy to Install

Clear and easy step-by-step directions coupled with minimal parts makes installation easy.

Interchanges with Other Manufacturers' Props

Turning Point's 500 series Installation Kits (for 4.25 and 4.75 inch gearcases) interchanges with other manufacturers' propellers. Upgrades and replaces Mercury® Flo-Torq II®, Michigan Wheel XHS®, and Solas® Rubex™ hub kit systems.